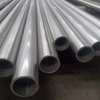

SUPER DUPLEX STEEL S32760 PIPE, UNS S32760 PIPES, SUPER DUPLEX STEEL 1.4410 PIPE, S32760 SUPER DUPLEX STEEL PIPE, S32760 SUPER DUPLEX STEEL PIPES MANUFACTURER, SUPER DUPLEX STEEL S32760 PIPES EXPORTERS, SUPER DUPLEX S32760 PIPES DISTRIBUTORS, SUPER DUPLEX S32760 PIPES SUPPLIER IN MUMBAI, INDIA.

ASTM A790 S32760 PIPE, GRADE S32760 SUPER DUPLEX STEEL SQUARE PIPE, AISI S32760 PIPE, SUPER DUPLEX S32760 RECTANGULAR PIPES DISTRIBUTORS, ASME SA790 S32760 POLISHED PIPE, JINDAL SUPER DUPLEX S32760 PIPE, SUPER DUPLEX STEEL PIPE S32760, INOX 1.4410 PIPE, AUSTENITIC SUPER DUPLEX STEEL S32760 ROUND PIPE, S32760 SUPER DUPLEX STEEL HOLLOW PIPE, SUPER DUPLEX S32760 PIPES SUPPLIER IN MUMBAI, INDIA.

Is an esteemed manufacturer, stockiest, supplier, and distributor of Super Duplex Steel UNS S32760 Pipes. Super Duplex Steel UNS S32760 Pipes is an austenitic-ferritic stainless steel that provides excellent resistance to pitting corrosion & crevice corrosion. The chemical composition, and a high chromium and molybdenum content, ensures high tensile strengths and exhibits high thermal conductivity and low thermal expansion. In both regards the characteristics of Super Duplex Steel UNS S32760 Pipes outperforms ordinary austenitic stainless steels. These pipes are intended for the application need exceptional strength and corrosion resistance. S32760 is comprised of molybdenum, chromium and nickel content. Higher composition of molybdenum and chromium and little addition of nitrogen results outstanding resistance to chloride pitting and crevice corrosion. However, the duplex structure offers good resistance to pitting and chloride stress corrosion cracking. Super Duplex Steel UNS S32760 Pipes should be limited to applications up to 316 degree C. Its service can be expanded up to elevated temperature but it can reduce corrosion resistance and toughness of grade.

Super duplex structure has exceptional mechanical properties. These pipes are available in different sizes ranging from ½†NB to 8†NB and we also customize these pipes as per our customer’s demand. The duplex structure of pipes are highly resistive to uniform corrosion in organic acid containing acids such as acetic and formic acids. Additionally, it has exceedingly resistance to inorganic acids that contain chlorides. The ferritic structure of pipes is resistive to stress cracking in warm chloride conditions. These tubes are used in various industries such as Power Generation, Off-Shore Oil Drilling Companies, Petrochemicals, Gas Processing, Specialty Chemicals, Pharmaceuticals, Pharmaceutical Equipment, Chemical Equipment, Sea Water Equipment, Heat Exchangers, Condensers, and Pulp and Paper Industry. We perform a number of tests on our pipes to ensure high standard quality. The tests conducted are eddy current testing, hydrostatic testing or ultrasonic examination, NDT and also chemical and physical property inspection. Some of the other tests are chemical analysis, Mechanical test, Rockwell hardness test, chemical test, intergranular corrosion test, positive material test, flattening test, flaring test, and third-party inspection and so on. Customer satisfaction is our top priority and we strive to meet the same.

| Place of Origin | Not Given |

| Minimum Order Quantity | Not Given |

| Supply Ability | Not Given |

| Packaging Details | Not Given |

| Delivery Details | Not Given |

Not Given