SMO 254 SEAMLESS PIPE, SMO 1.4547 SEAMLESS PIPE, UNS S31254 SEAMLESS PIPES, 254 SMO SEAMLESS PIPE, SMO 254 SEAMLESS PIPES EXPORTERS, 254 SMO SEAMLESS PIPES MANUFACTURER, 6 MOLY 254 SEAMLESS PIPES DISTRIBUTORS, 6 MOLY 254 SEAMLESS PIPES SUPPLIER IN MUMBAI, INDIA.

SMO SEAMLESS PIPE 254, 6 MOLY 254 SEAMLESS BOILER PIPES DISTRIBUTORS, AUSTENITIC SMO 254 SEAMLESS ROUND PIPE, JINDAL 6 MOLY 254 SEAMLESS PIPE, ASME SA312 254 POLISHED SEAMLESS PIPE, INOX 1.4547 SEAMLESS PIPE, AISI 254 SEAMLESS PIPE, GRADE 254 SMO SEAMLESS OVAL PIPE, ASTM A312 254 SEAMLESS PIPE, 254 SMO SEAMLESS HOLLOW PIPE, 6 MOLY 254 SEAMLESS PIPES SUPPLIER IN MUMBAI, INDIA.

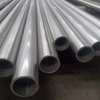

Is a prominent manufacturer, supplier, and distributor of Stainless Steel 254SMO Seamless Pipes. 254SMO is a high-alloy austenitic SS is designed to work in high resistance to general corrosion and stress corrosion cracking. These SS Seamless pipes show excellent resistance to pitting and crevice corrosion. They also have good weld ability and is developed to be used in seawater and other aggressive chloride-bearing media. Alloy 254 SMO SS Seamless Pipes offer superior oxidation resistance. A pipe without a seam or weld is called as Seamless Pipe. Our SMO 254 Pipes can withstand high mechanical stress and high pressure can work in high temperatures and corrosive environments. Stainless Steel 254SMO Seamless Pipes have excellent corrosion resistance in solutions containing halides such as chloride and bromide ions. 254SMO Seamless Pipes are resistant to stress corrosion cracking in chloride-containing solutions at temperatures below 60 degrees C.

The full size of our Stainless Steel 254SMO Seamless Pipe is available in different sizes and dimensions. These Stainless Steel 254SMO Seamless Pipes have high pitting and crevice corrosion with strength. Stainless Steel 254SMO Seamless Pipes are used in various application industries such as Oil and Gas Industry, Paper and Pulp industries, Offshore Drilling, Seawater cooling procedures, along and in acetic, sulphuric and phosphoric acid treating plants. To ensure the best quality of our products, we put them to various kinds of tests. Some of the chemical test/ spectro analysis, tests are micro and macro test, intergranular corrosion test, and Mechanical test are the tests are performed in our facility. Other tests are the hardness test, tensile test, flaring test, flattening test, ultrasonic test, positive material test, radiographic test, x-ray test, prompt test, firmness test, pitting corrosion test, and visual inspection. We are engaged in providing the best services to our valued customers at .Our team strives hard to manufacture and maintain the high quality standards of our products to meet both national and international standards. Customer is our prime goal and hence we have received frequent customer acclamations.

| Place of Origin | Not Given |

| Minimum Order Quantity | Not Given |

| Supply Ability | Not Given |

| Packaging Details | Not Given |

| Delivery Details | Not Given |

Not Given