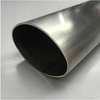

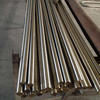

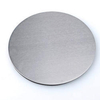

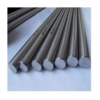

We are providing our clients a high-quality range of 15-5 PH Stainless Steel Round Bar. Our offered range is developed using high-quality raw material and technology. These are widely appreciated by a large number of clients due to their robustness and precisely-engineering.

15-5 stainless steel is a martensitic, precipitation-hardening material with chromium, nickel and copper. It is often a first choice in the aerospace industry for fasteners and structural components. Its unique structure provides increased toughness and better corrosion resistance than its predecessor, 17-4 PH. Both inclusion control and a minimized amount of delta ferrite as compared to 17-4 stainless steel contribute to the greater toughness of 15-5. The alloy is further strengthened by a low temperature heat treatment which precipitates a copper containing phase in the alloy. 15-5 PH is able to meet the stringent mechanical properties required in the aerospace and nuclear industries.

Chemical Composition : Stainless Steel 15-5 Ph

Carbon (C) = 0.07 max

Chromium (Cr) = 14 - 15.5

Copper (Cu) = 3 - 5 max

Manganese (Mn) = 1 max

Nickel (Ni) = 3.5 - 5.5 max

Niobium + Tantalum (Nb+Ta) = 0.15 - 0.45

Phosphorus (P) = 0.04 max

Silicon (Si) = 1 max

Sulphur (S) = 0.03 max

Iron (Fe) = Balance

Specifications :

AMS 5659 TYPE 2

ASTM-A-484

UNS-S15500

Applications:

- Marine gas turbine compressor sections

- Hallow shafts

- Paper mill equipment

- Engine parts

- Aircraft components

- Gears

- Fittings and fasteners

- Nuclear reactor components, etc.

| Place of Origin | Not Given |

| Minimum Order Quantity | Not Given |

| Supply Ability | Not Given |

| Packaging Details | Not Given |

| Delivery Details | Not Given |

Not Given