| Chemical Requirements | Grade I | ||

| Copper | 56.0 - 59.0% | ||

| Lead | 2.0 to 3.50% | ||

| Iron | 0.35% max. | ||

| Total Imp. Excl. Iron | 0.70% max. | ||

| Zinc | Remainder | ||

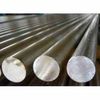

| Physical Properties | |||

| Condition | Size | T.S. MPA | EL% Min |

| Annealed (O) | 6-25 25-50 50 above | 345 315 285 | 12 17 22 |

| Half-Hard (HB) | 6-12 12-25 25-50 50 above | 405 395 355 325 | 4 6 12 17 |

| Hard (HD) | 6-12 12-25 | 550 490 | - 4 |

| Fabrication Properties | |||

| Capacity for being | |||

| Cold worked | Poor | ||

| Hot formed | Fair | ||

| Machinability Rating | 100% | ||

| Suitability for soldering | Excellent | ||

| Suitability for Brazing | Good | ||

| Uses | |||

| Precision Components, Hardware, Hinges, Lock Bodies, Screws, Nuts & Bolts | |||

| Place of Origin | Not Given |

| Minimum Order Quantity | Not Given |

| Supply Ability | Not Given |

| Packaging Details | Not Given |

| Delivery Details | Not Given |

Not Given