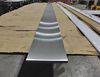

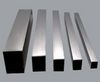

The manufacturing process and strict tests foreseen for the cold drawn SEAMLESS and WELDED tubes give as result a fine grain steel with high pureness degree together with a high dimensional precision.

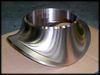

APPLICATIONS

These tubes are intended to resist to internal pressure and are therefore used for the manufacture of cylinders. They are produced in all the sizes used for hydraulic and pneumatic applications, in different steelgrades and delivery conditions.

NORMS,

COLD DRAWN SEAMLESS TUBES - EN 10305-1

COLD DRAWN WELDED TUBES - EN10305-2

DIMENSIONAL TOLERANCES ACCORDING TO EN 10305-1/2

O.D.: see dimensional table for tubes suitable for honing.

W.T.: welded tubes: ±7.5% with a minimum ±0.1 mm

seamless tubes: ±10% with a minimum ±0.1 mm

ECCENTRICITY: welded tubes: ≤ 7.5%

seamless tubes: ≤ 10%

to be calculated with the follwing formula:

Max.W.T.- Min W.T.

_____________________ *100

Max.W.T.+ Min W.T.

STRAIGHNESS:

for OD ≤ 260 mm

if ReH ≤ 500 Mpa 0.0015 L;

if ReH > 500 Mpa 0.002 L;

for ID >260 mm

if ReH ≤ 500 Mpa 0.0025 L;

if ReH ≤ 500 Mpa 0.003 L;

L= total lenght of the tube, max. values to be checked on the total tube length.

| Place of Origin | Not Given |

| Minimum Order Quantity | Not Given |

| Supply Ability | Not Given |

| Packaging Details | Not Given |

| Delivery Details | Not Given |