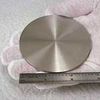

Inconel 617® consists of nickel-chromium-cobalt and – molybdenum. These elements make Inconel 617® highly resistant to oxidation and carburization. Inconel 617® can be easily fabricated; it can be hot formed up to 2200º F, and cold formed at 1900º F. Inconel 617® has excellent weldability. Inconel 617® is used for ducting, transition liners in both aircraft and land based gas turbines, and combustion cans.Available forms are seamless pipe, welded pipe, seamless tube, welded tube, bar, wire, sheet, plate, forgings, pipe fittings and flanges.

| Place of Origin | Not Given |

| Minimum Order Quantity | Not Given |

| Supply Ability | Not Given |

| Packaging Details | Not Given |

| Delivery Details | Not Given |

Sheet/Plate : ASME SB-168, AMS 5888 ,AMS 5889

Round Bar : ASME SB-166, AMS 5887

Forgings : ASME SB-564, AMS 5887