We are counted among the leading traders and importers of Monal Products in the entire domestic market. All our products are sourced from reputed manufacturers, who specialize in developing the entire range as per the application needs of our clients. Our vendors make use of high-grade raw material and sophisticated methodologies for manufacturing these Monal products.

Monel 400 is a combination of nickel and copper and is hardened by cold working only. This alloy is widely renowned for for its corrosion resistant properties against flowing sea – water and is extensively used for marine applications. Monel is also extremely resistant to stress corrosion cracking in most freshwaters. High temperature ( up to 1000 °F) has no effect on this alloy and it also has excellent mechanical properties at subzero temperatures.

Monel 400 is available in many forms like wire , Round bar, Forged bar , hex bar , Flat bar , Circles , Ring , Tube , seamless Pipe , Welded / ERW Pipe , Sheet , Plate , Coil , Flanges , fasteners , Socket weld Fittings , ferrule fittings , Buttweld fittings Like cap , elbow , tee. UNS N04400 is available in various forms like Monel 400 wire , Monel 400 Round bar, Monel 400 Forged bar , Monel 400 hex bar , Monel 400 Flat bar , Monel 400 Circles , Monel 400 Ring , Monel 400 Tube , Monel 400 seamless Pipe , Monel 400 Welded / ERW Pipe , Monel 400 Sheet , Monel 400 Plate , Monel 400 Coil , Monel 400 Flanges , Monel 400 fasteners , Monel 400 Socket weld Fittings , Monel 400 ferrule fittings , Monel 400 Buttweld fittings Like cap , elbow , tee , Reducer.

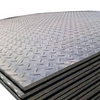

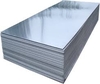

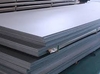

Alloy 20 Plate

Alloy 20 is a nickel-iron-chromium alloy with some amounts of copper and molybdenum. The nickel in this alloy makes it resistant to chloride-ion stress-corrosion cracking. On the other hand, copper and molybdenum make it resistant to reducing environments and also provide good resistance to pitting and crevice corrosion. The chromium makes it suitable for work with chemicals like nitric acid, by adding resistance to oxidizing environments. The molybdenum, is also essential for this alloy as it helps to reduce the effect of carbide precipitation during welding and thereby increasing alloy’s resistance to intergranular corrosion.

INCO alloy 20 is extremely resistant to corrosion in sulfuric acid environments and hence finds utility with this acid as well as in production of gasoline, solvents, explosives, inorganic and organic chemicals etc. In case of other application, INCO alloy 020 is easily prepared to produce mixing tanks, heat exchangers, process piping, pickling equipment, pumps, valves, fasteners and fittings

We offer wide range of alloy 20 like alloy 20 wire , alloy 20 Round bar, alloy 20 Forged bar , alloy 20 hex bar , alloy 20 Flat bar , alloy 20 Circles , alloy 20 Ring , alloy 20 Tube , alloy 20 seamless Pipe , alloy 20 Welded / ERW Pipe , alloy 20 Sheet , alloy 20 Plate , alloy 20 Coil , alloy 20 Flanges , alloy 20 fasteners , alloy 20 Socket weld Fittings , alloy 20 ferrule fittings , alloy 20 Buttweld fittings Like cap , elbow , tee.

Chemical Analysis of Alloy 20

C | Ni | Mo | Co | Ir | M | Cr | Si | Su | Ti | Al | Pho |

.19.00-21.00 | 32.00-38.00 | 2.00-3.00 | 3.00-4.00 | Bal. | 2.00max | 0.07max | 1.00max | 0.035max | 0.045max |

Alloy 20 Plate / Sheet | Alloy 20 Round Bar | Alloy 20 Pipes | Alloy 20 Tube | Alloy 20 Fittings | Alloy 20 Forgings |

SB- B162 / B160 | SB- B162 / B160 | SB- B161 / B725 | SB- B366 | SB- B564 |

| Place of Origin | Not Given |

| Minimum Order Quantity | Not Given |

| Supply Ability | Not Given |

| Packaging Details | Not Given |

| Delivery Details | Not Given |

Not Given