Description Of Stainless Steel

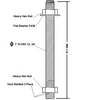

Stainless steel is used for corrosion-resistant tools Equipments and Products such as Stud Bolts , Hex Bolts , Pipe , Flanges and Fittings.

Stainless steel does not readily corrode, rust or stain with water as ordinary steel does. However, it is not fully stain-proof in low-oxygen, high-salinity, or poor air-circulation environments. There are different grades and surface finishes of stainless steel to suit the environment the alloy must endure. Stainless steel is used where both the properties of steel and corrosion resistance are required.

Stainless steel differs from carbon steel by the amount of chromium present. Unprotected carbon steel rusts readily when exposed to air and moisture. This iron oxide film (the rust) is active and accelerates corrosion by forming more iron oxide; and, because of the greater volume of the iron oxide, this tends to flake and fall away. Stainless steels contain sufficient chromium to form a passive film of chromium oxide, which prevents further surface corrosion by blocking oxygen diffusion to the steel surface and blocks corrosion from spreading into the metal's internal structure. Passivation occurs only if the proportion of chromium is high enough and oxygen is present.

Properties

Oxidation

High oxidation resistance in air at ambient temperature is normally achieved with additions of a minimum of 13% (by weight) chromium, and up to 26% is used for harsh environments. The chromium forms a Passivation layer of chromium(III) oxide (Cr2O3) when exposed to oxygen. The layer is too thin to be visible, and the metal remains lustrous and smooth. The layer is impervious to water and air, protecting the metal beneath, and this layer quickly reforms when the surface is scratched. This phenomenon is called Passivation and is seen in other metals, such as aluminium and titanium. Corrosion resistance can be adversely affected if the component is used in a non-oxygenated environment, a typical example being underwater keel bolts buried in timber.

When stainless steel parts such as nuts and bolts are forced together, the oxide layer can be scraped off, allowing the parts to weld together. When forcibly disassembled, the welded material may be torn and pitted, an effect known as galling. This destructive galling can be avoided by the use of dissimilar materials for the parts forced together, for example bronze and stainless steel, or even different types of stainless steels (martensitic against austenitic). However, two different alloys electrically connected in a humid environment may act as a voltaic pile and corrode faster. Nitronic alloys made by selective alloying with manganese and nitrogen may have a reduced tendency to gall. Additionally, threaded joints may be lubricated to prevent galling. Low-temperature carburizing is another option that virtually eliminates galling and allows the use of similar materials without the risk of corrosion and the need for lubrication.

Acids

Stainless steel is generally highly resistant to attack from acids, but this quality depends on the kind and concentration of the acid, the surrounding temperature, and the type of steel. Type 904 is resistant to sulfuric acid at room temperature, even in high concentrations; type 316 and 317 are resistant below 10%, and 304 should not be used in the presence of sulfuric acid at any concentration. All types of stainless steel resist attack from phosphoric acid, 316 and 317 more so than 304; Types 304L and 430 have been successfully used with nitric. Hydrochloric acid will damage any kind of stainless steel, and should be avoided.

Bases

The 300 series of stainless steel grades is unaffected by any of the weak bases such as ammonium hydroxide, even in high concentrations and at high temperatures. The same grades of stainless exposed to stronger bases such as sodium hydroxide at high concentrations and high temperatures will likely experience some etching and cracking, especially with solutions containing chlorides such as sodium hypochlorite.

Organics

Types 316 and 317 are both useful for storing and handling acetic acid, especially in solutions where it is combined with formic acid and when aeration is not present (oxygen helps protect stainless steel under such conditions), though 317 provides the greatest level of resistance to corrosion. Type 304 is also commonly used with formic acid though it will tend to discolor the solution. All grades resist damage from aldehydes and amines, though in the latter case grade 316 is preferable to 304; cellulose acetate will damage 304 unless the temperature is kept low. Fats and fatty acids only affect grade 304 at temperatures above 150 °C (302 °F), and grade 316 above 260 °C (500 °F), while 317 is unaffected at all temperatures. Type 316L is required for processing of urea.

Electricity and magnetism

Poor selection of materials can cause galvanic corrosion to other metals in contact with stainless steel, Like steel, stainless steel is a relatively poor conductor of electricity, with lower electrical conductivity than copper. Other metals in contact with stainless steel in a damp environment may suffer galvanic corrosion. even though the stainless metal may be unaffected.

Ferritic and martensitic stainless steels are magnetic. Annealed austenitic stainless steels are non-magnetic. Work hardening can make austenitic stainless steels slightly magnetic.

3D printing

Some 3D printing providers have developed proprietary stainless steel sintering blends for use in rapid prototyping. One of the more popular stainless steel grades used in 3D printing would be 316L Stainless steel. Due to the high temperature gradient and fast rate of solidification, stainless steel manufactured via 3D printing tends to have more refined microstructures. This in turn results in better mechanical properties. However, stainless steel is not used as much as materials like Ti6Al4V in the 3D printing industry. This is because stainless steel manufactured via the traditional methods tends to be more economically competitive.

Types of stainless Steel

There are different types of stainless steels: when nickel is added, for instance, the austenite structure of iron is stabilized. This crystal structure makes such steels virtually non-magnetic and less brittle at low temperatures. For greater hardness and strength, more carbonis added. With proper heat treatment, these steels are used for such products as razor blades, cutlery, and tools.

Significant quantities of manganese have been used in many stainless steel compositions. Manganese preserves an austenitic structure in the steel, similar to nickel, but at a lower cost.

Stainless steels are also classified by their crystalline structure:

· Austenitic, or 200 and 300 series, stainless steels have an austenitic crystalline structure, which is a face-centered cubic crystal structure. Austenite steels make up over 70% of total stainless steel production. They contain a maximum of 0.15% carbon, a minimum of 16% chromium and sufficient nickel and/or manganese to retain an austenitic structure at all temperatures from the cryogenic region to the melting point of the alloy.

· 200 Series—austenitic chromium-nickel-manganese alloys. Type 201 is harden able through cold working; Type 202 is a general purpose stainless steel. Decreasing nickel content and increasing manganese results in weak corrosion resistance.

· 300 Series—The most widely used austenite steel is the 304, also known as 18/8 for its composition of 18% chromium and 8% nickel.[7] 304 may be referred to as A2 stainless (not to be confused with AISI grade A2 air hardening alloy tool steel containing about 5% chromium). The second most common austenite steel is the 316 grade, also referred to as A4 stainless and called marine grade stainless, used primarily for its increased resistance to corrosion. A typical composition of 18% chromium and 10% nickel, commonly known as 18/10 stainless, is often used in cutlery and high-quality cookware. 18/0 is also available.

· Super austenitic stainless steels, such as Allegheny Ludlum alloy AL-6XN and 254SMO, exhibit great resistance to chloride pitting and crevice corrosion because of high molybdenum content (>6%) and nitrogen additions, and the higher nickel content ensures better resistance to stress-corrosion cracking versus the 300 series. The higher alloy content of super austenitic steels makes them more expensive. Other steels can offer similar performance at lower cost and are preferred in certain applications, for example ASTM A387 is used in pressure vessels but is a low-alloy carbon steel with a chromium content of 0.5% to 9%.[8] Low-carbon versions, for example 316L or 304L, are used to avoid corrosion problems caused by welding. Grade 316LVM is preferred where bio compatibility is required (such as body implants and piercings).The "L" means that the carbon content of the alloy is below 0.03%, which reduces the sensitization effect (precipitation of chromium carbides at grain boundaries) caused by the high temperatures involved in welding.

· Ferritic stainless steels generally have better engineering properties than austenitic grades, but have reduced corrosion resistance, because of the lower chromium and nickel content. They are also usually less expensive. Ferritic stainless steels have a body-centered cubic and contain between 10.5% and 27% chromium with very little nickel, if any, but some types can contain lead. Most compositions include molybdenum; some, aluminium or titanium. Common ferritic grades include 18Cr-2Mo, 26Cr-1Mo, 29Cr-4Mo, and 29Cr-4Mo-2Ni. These alloys can be degraded by the presence of chromium, an inter-metallic phase which can precipitate upon welding.

· Martensitic stainless steels are not as corrosion-resistant as the other two classes but are extremely strong and tough, as well as highly machine-able and can be hardened by heat treatment. Martensitic stainless steel contains chromium (12–14%), molybdenum (0.2–1%), nickel (less than 2%), and carbon (about 0.1–1%) (giving it more hardness but making the material a bit more brittle). It is quenched and magnetic.

· Duplex steel stainless steels have a mixed microstructure of austenite and ferrite, the aim usually being to produce a 50/50 mix, although in commercial alloys the ratio may be 40/60. Duplex stainless steels have roughly twice the strength compared to austenitic stainless steels and also improved resistance to localized corrosion, particularly pitting, crevice corrosion and stress corrosion cracking. They are characterized by high chromium (19–32%) and molybdenum (up to 5%) and lower nickel contents than austenitic stainless steels.

· The properties of duplex stainless steels are achieved with an overall lower alloy content than similar-performing super-austenitic grades, making their use cost-effective for many applications. Duplex grades are characterized into groups based on their alloy content and corrosion resistance.

· Lean duplex refers to grades such as UNS S32101 (LDX 2101), S32202 (UR2202), S32304, and S32003.

· Standard duplex is 22% chromium with UNS S31803/S32205 known as 2205 being the most widely used.

· Super duplex is by definition a duplex stainless steel with a Pitting Resistance Equivalent Number (PREN) > 40, where PREN = %Cr + 3.3x(%Mo + 0.5x%W) + 16x%N. Usually super duplex grades have 25% chromium or more and some common examples are S32760 (Zeron 100 via Rolled Alloys), S32750 (2507) and S32550 (Ferralium),.

· Hyper duplex refers to duplex grades with a PRE > 48 and at the moment only UNS S32707 and S33207 are available on the market.

· Precipitation-hardening martensitic stainless steels have corrosion resistance comparable to austenitic varieties, but can be precipitation hardened to even higher strengths than the other martensitic grades. The most common, 17-4PH, uses about 17% chromium and 4% nickel.

Grades.

EN Steel grades and SAE steel grades

There are over 150 grades of stainless steel, of which 15 are most commonly used. There are a number of systems for grading stainless and other steels, including US SAE steel grades.

| Place of Origin | Not Given |

| Minimum Order Quantity | Not Given |

| Supply Ability | Not Given |

| Packaging Details | Not Given |

| Delivery Details | Not Given |

Applications Of Stainless Steel